.

.

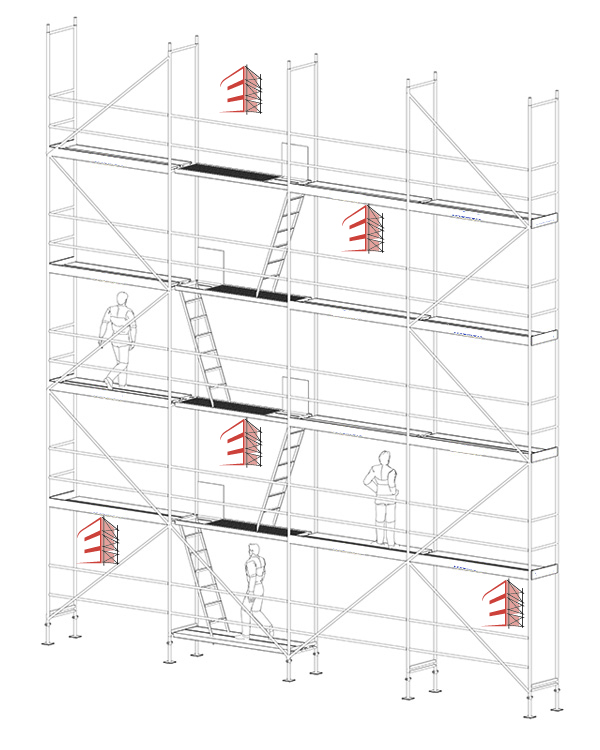

Safe Construction Scaffolding

H Type Safe Scaffolding System is a widely used scaffolding system that is used on the facades of the buildings, offers a safe working environment, can be installed and disassembled quickly, can be easily stored, has many advantages with its structure that can work fully compatible with the facades.

Advantages

100 m. It can be safely installed up to a height.

It can be installed and disassembled quickly, does not require hand tools, saves time.

It is light and easily stowed.

It does not take up much space while storing, it saves space.

Quality and Safety

Joint welds are made untouched in robotic lines.

Special forged pins resistant to rupture, breakage and cut are used in scaffold panels.

Steel platforms and heels are manufactured by giving a special form with a roll-form machine for high strength.

Fixed parts in the system are coated with hot dip galvanize against corrosion.

Certificated pipes, profiles and sheets that have passed mechanical tests are used.

Usage areas

It is used safely for repairs, plaster, paint, coating and insulation in the construction of houses, hospitals, stadiums, business and shopping centers, restoration projects, elevator and gallery spaces.

System features

The working principle of the system is based on the rationale of the scaffolding panels by overlapping them.

Each module has 2 horizontal fasteners at waist and knee level, they are locked by attaching to the pins on the panel.

A safe working environment is created by placing 2 steel platforms on each floor. The hooks of the steel platforms are locked between the scaffolding panels and cannot be removed during operation.

The passage between the stairs and the floors is ensured safely without installing a separate stairway tower.

Access to every point of the facades is provided with side elements such as console, lattice beam and clamps.

The safety of the system is completed with side rails, heel rails and wall fasteners.